How the Choice of Abrasive Media Impacts Blasted Profiles

The blasting process involves removing troublesome mill scale, corrosion or previous coatings to create a suitable profile which provides a better key for subsequent coatings applied. However, as the profile is largely impacted by the abrasive chosen for the blasting application, it is important to understand the effect of abrasive choice.

The shape of blasting particles fall broadly into the categories of shot and grit with each summarised below:

|

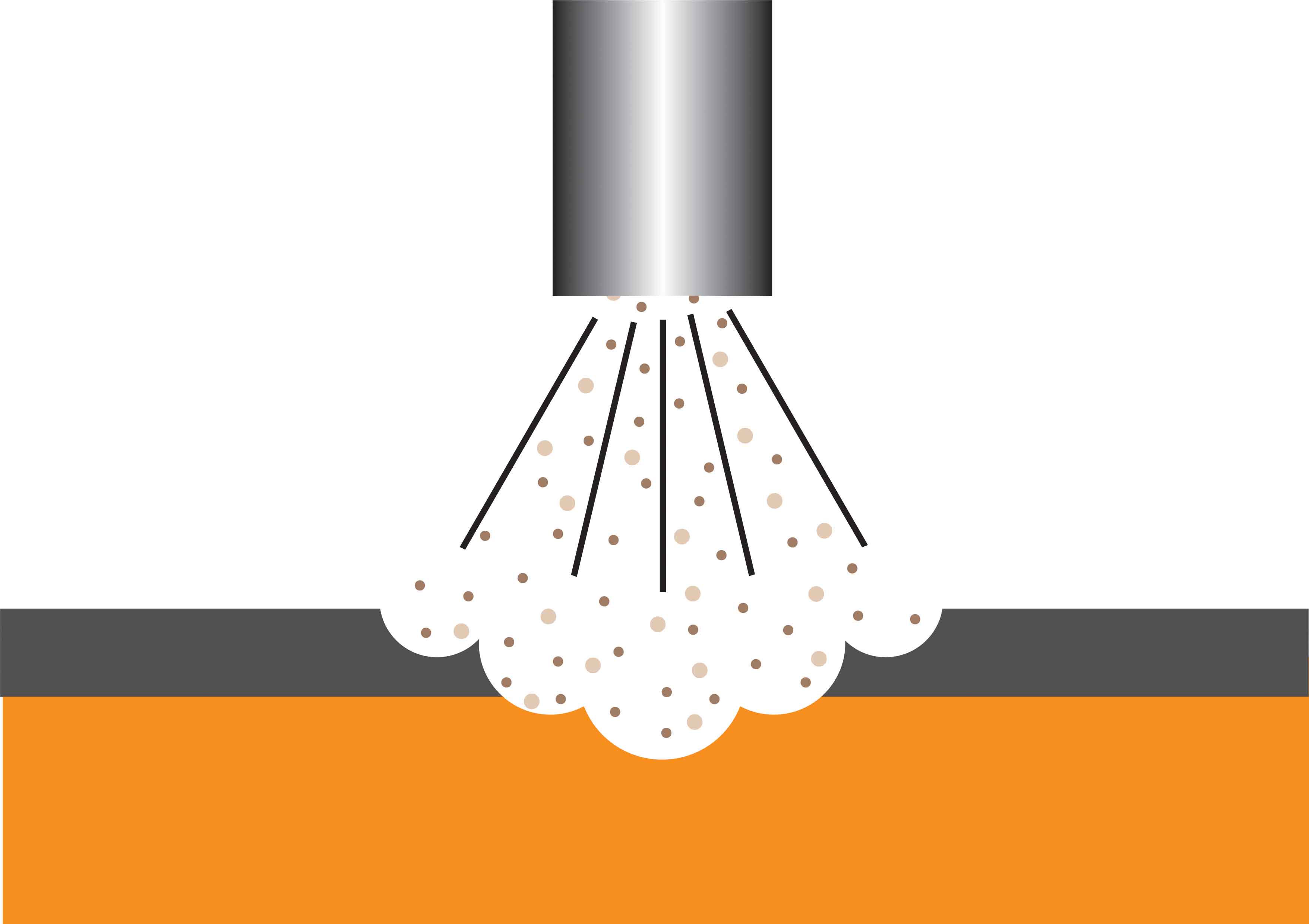

Shot Abrasives Shot abrasives are spherical particles that distribute their impact over a larger area, moderating the impact and creating a round-bottomed dimple in the surface of the substrate. Sometimes labelled a peened finish, the effect of shot blast treatment is likely to be a semi-reflective sheen appearance. |

|

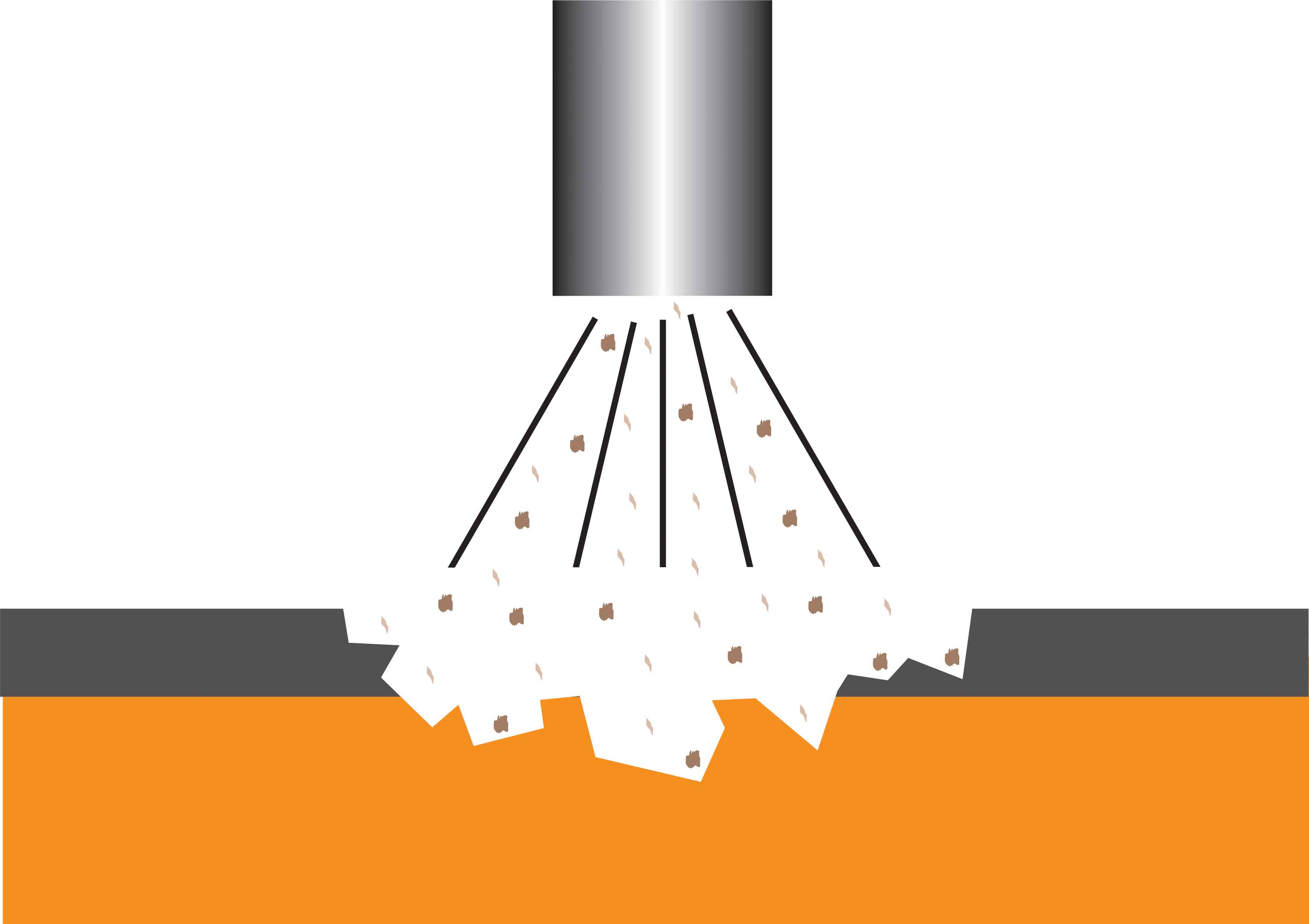

Grit Abrasives Grit abrasives are angular particles. Their impact may be concentrated on a point of the particle or a sharp edge, generating an etched, matt finish that bright, but non-reflective. |

As well as shape, particle size also has an important effect on the number of impacts per second of blasting, so it is advisable to use media of the smallest screen size that will do the work. There will be a higher number of smaller particles in a given volume than larger particles, hence more impacts on the surface, reducing process time to a minimum. Larger particles may be capable of creating bigger indentations and more texture in the surface whereas smaller ones produce dimples or angular dents of a lesser diameter.

In some instances, the choice of media screen size is dictated by surface features such as holes or narrow places where shot or grit may penetrate less effectively, become entrapped or lodge in recesses of the component.

To summarise, the media used during the blasting process produces different visual surface finishes; large particles create bigger indentations in the surface whilst smaller ones produce dimples or angular dents of lesser diameter.

Elcometer have produced a technical article that explains the methods used to measure blasted surface profiles which can be accessed by clicking here.